Key challenges

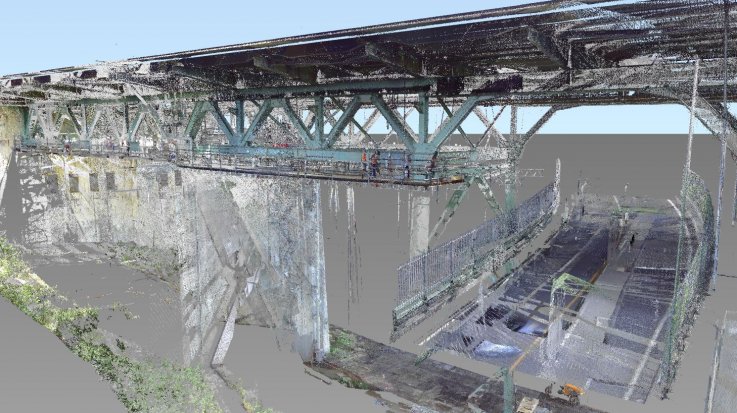

Difficult-to-access locations of surveys, overhead job on footbridges, vast amount of plates and bolts to verifiy.

Services rendered

Numerous 3D scans were executed to survey all the plates and bolt to be verified, accordingly to our client needs. From the resulting point clouds of the surveys, we established a procedure to create verification drawings. With these drawings, our client was able to rectify his fabrication drawings and therefore limit on site adjustments throughout installation.

Spinoffs

With the 3D scans, surveying times have been greatly reduced. Furthermore, with the 3D surveys precision, our client was able to reduce the number of adjustments by more than 90% throughout on site installation of the plates and bolts. Our services allowed the client to achieve his project faster, as well as saving substantially in costs by several hundreds of thousands of dollars.